Sintered porous plastic material

In the space of advanced materials engineering, the synthesis of porous plastic materials stands as a testament to the strides

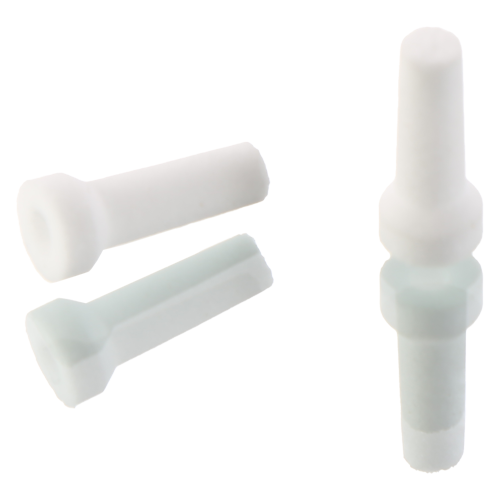

Samples are an essential part of almost every dissolution test as they help produce accurate results. To ensure that particles from the tablet sample do not interfere with the spectrophotometer, filters are used to trap them. Most manufacturers opt for using filters at the end of the sampling cannula. These cannula filters are typically made of UHMW Polyethylene for larger porosities or Poroplast for lower porosities (1-5µm). Importantly, these filters are chemically inert and do not react with most compounds.

Cannula filters have a significant surface area, which can potentially impact the hydrodynamics within the vessel. However, they offer a good flow rate and are particularly useful when dealing with high levels of particulates. By preventing these particulates from blocking the sample probes, the filters ensure smooth and uninterrupted testing. It’s worth noting that different manufacturers recommend specific filters for use with their probes, and not all filters are interchangeable due to variations in probe diameter.

With dissolution filters, porosities are nominal and represent an average pore size rather than an absolute one. Thus a 35µm and 40µm filter will perform much the same.

Some low-dimension sample probes require an in-line filter disc (or filter frit) which has a lower surface area than a cannula filter. These are designed to keep the filtration process outside of the vessel but may suffer from blocking due to the lower surface area.

The quality of filters can be variable. Some materials may leach impurities more than others and a good starting point is to use a filter that is certified and contains no heavy metals.

Dissolution filters are available from 1um up to 70um porosity. The porosity quoted is an ‘average’ porosity and not an absolute because of the nature of the material. Thus a 35um filter will allow some particles to pass that are larger than 35um and will also stop some smaller particles.

In general, the choice of porosity will be determined by the sample. If it is too high then un-dissolved particles will pass through the filter and affect the results by dissolving in the sample container rather than the vessel, giving a high result. It also means that those particles have been removed from the vessel resulting in low results subsequently. If it is too low then the flow rate may not be sufficient and cavitation can occur, particularly with automated systems

First Column | Second Column | Third Column | Fourth Column |

|---|---|---|---|

First Row | Second Row | Third Row | Fourth Row |

In the space of advanced materials engineering, the synthesis of porous plastic materials stands as a testament to the strides

Goharan Gostar Nadin Company is a group of specialized engineers in the field of membranes and filters that constantly strive to provide the most effective solutions, achieve the most efficient results, and create the best experience for their customers by utilizing up-to-date knowledge and innovative technologies because they are our most valuable asset and highest priority.

Iran Office: 2nd Floor, no. 31, Qasemi St., Habibollah St., Azadi St., Tehran

Tel.: +989129309178

Turkey Office: Istanbul

Tel.: 00905377067466

Email: info@goharangostar.com

© 2023-2024 Goharan Gostar Nadin, Inc. All rights reserved.